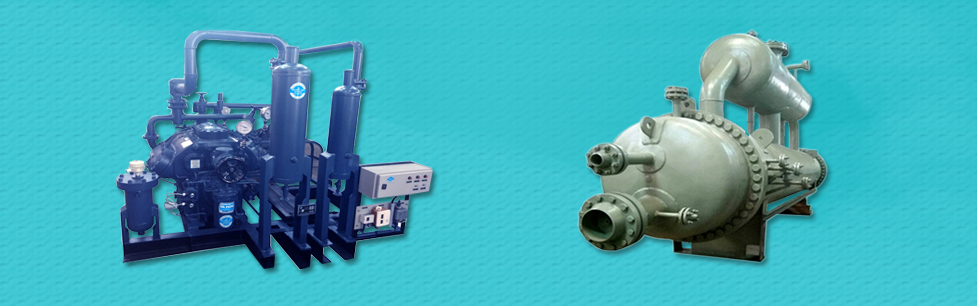

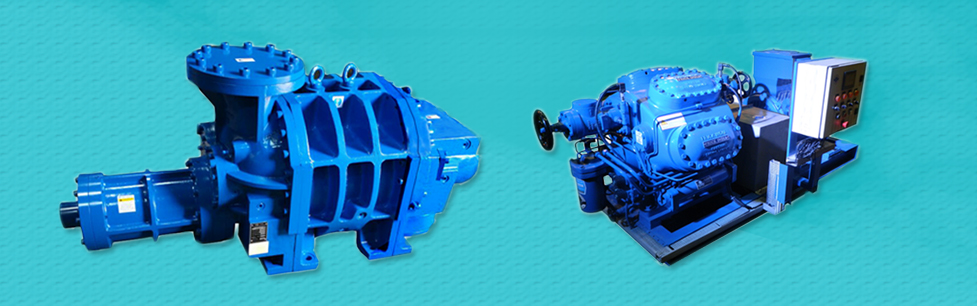

Frick Rotary Twin screw compressor units in Ten high efficiency models, range in capacity from 255 CFM through 2000 CFM

at 2950 RPM. Standard units are designed for use on ammonia, halocarbon and hydrocarbon refrigerants at pressure ratios

upto 26:1.

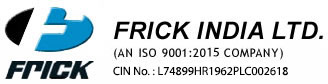

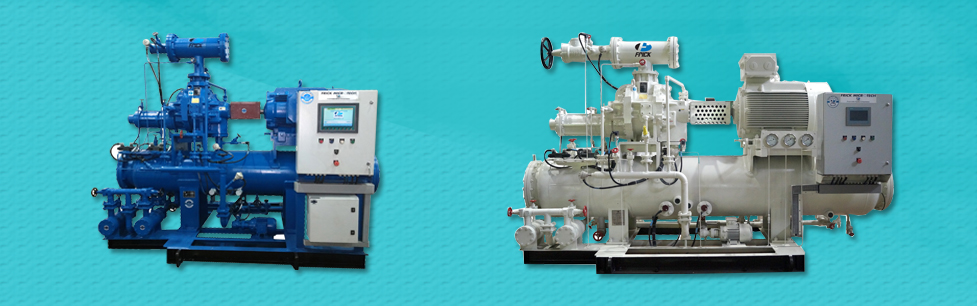

The compact, vibration-free Frick rotary screw compressor packages are designed for all industrial refrigeration and airconditioning

requirements. These screw compressors can run for almost all gases like R-717,R-22,R-134a, R290, R-404a, R-

1270 etc. For other gas applications custom-built packages can be offered.